DC motor is more efficient, but there is a certain ratio of loss, leading to failure factors include: the initial resistance of the winding, brush friction and eddy current loss.

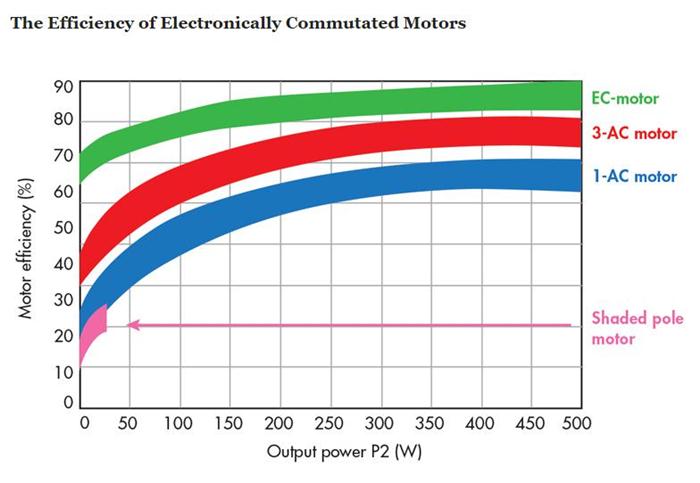

The figure compares the motor efficiency of the electronic commutation motor, three-phase induction AC motor, single-phase AC induction motor and shaded pole motor.

Electronic commutation motor introduction and advantages

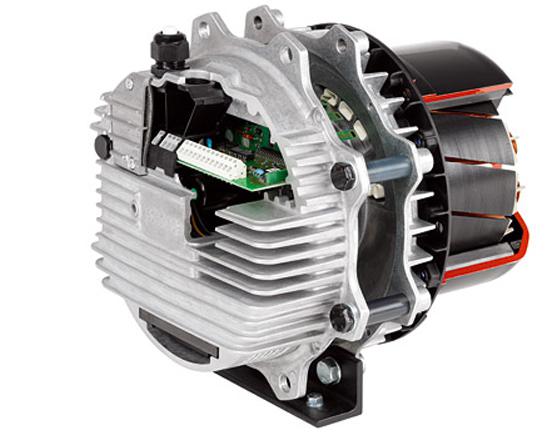

Electronic commutation motor is a brushless DC motor controlled by external electronic devices, which may be electronic circuit boards, it may be inverter. Mechanical rectification depends on the implementation of electronic circuits, circuit board can change the phase of the fixed windings to ensure that the motor rotation, can provide the appropriate amount of armature current. Higher accuracy can be achieved if the current is delivered in the right direction over a precise period of time. Because the speed of the electrode is controlled by the external electronics, the electronically commutated motor does not have the problem of limited synchronous speed.

For electronically commutated motors, the commutation circuit has a pulse width modulation of 4-20 mA and a voltage of 0-10 V, which sets the motor speed in the range of 10% -100%. Just use the integrated circuit, we can complete the monitoring of the electronic rectifier motor, the designer can provide the corresponding feedback. Electronic commutation motor can also provide soft start, and noise and motor temperature is low.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite