"The overall development of perovskite technology is now very clear and clear, and people who do not see this may delay the timing." For the commercial mass production of perovskite photovoltaic cell technology, one returned to China to start a business in calcium. The doctoral confidence in the field of titanium ore is real.

According to the doctor who did not want to be named, in addition to his company, many companies around the world are speeding up the pace of commercial mass production of perovskite batteries, which is said to include the single crystal in western China. Leading silicon companies. "From their recent secret recruitment situation, it should be already preparing for commercial trial production."

In terms of research and development, “almost all science and engineering colleges are conducting research on perovskite technology and have accumulated a large number of talents for the industry.”

He believes that as the photovoltaic power generation technology that China's PV industry has participated in for the first time from the research and development stage, the industrialization timing of perovskite batteries has gradually matured, and the commercialization speed is likely to exceed the imagination of many people.

Raw materials determine the prospects of technology

In his view, whether a technology has a future can be judged from two aspects: technical economy and easy accessibility of raw materials.

"The promotion of a new technology must first be supported by the technology of a mature industry. Just as the industrialization of crystalline silicon cells is based on the semiconductor industry technology, the manufacturing of perovskite batteries can be completely used in the LCD panel industry. Technology, and the technical and process requirements are also lower."

That is to say, like the semiconductor devices and processes in which crystalline silicon cells use "dimension reduction", perovskite batteries only need "dimension reduction" liquid crystal panel production equipment and processes.

Second, raw materials cannot be scarce.

“Perovskite is a compound battery. Its raw materials are derived from basic chemical materials. There are up to tens of thousands of raw materials to choose from. How can there be a shortage?”

Compared to the demand for silicon in crystalline silicon cells, perovskite batteries require much less raw materials. The silicon wafer component of a 72-cell battery consumes about 1 kilogram of silicon, while the equivalent-area perovskite battery component requires only about 2 grams of perovskite.

In addition to the scarcity problem, in this doctor's view, the breakthrough of materials may be more important for the development of technology. He believes that only relying on technologies with designable and iterable materials will have more room for development in the future.

“The use of materials from simple to complex, to the ability to design materials, is the ultimate path.” He said that the most fundamental reason for the rapid increase in the photoelectric conversion efficiency of perovskite batteries in recent years is Because perovskite is a type of material, not a material.

“While crystalline silicon cells and other thin-film cells are basically one or several materials, it is still difficult to find alternatives.”

"Best Photovoltaic Cell Materials"

He believes that the crystal structure of perovskites determines that it is "even the best photovoltaic cell material that has been discovered so far."

He said that the perovskite pyropeptide is a three-line peptide, and the base peptide is a single-line peptide, and its carriers cannot fall back after the excitation because carriers are difficult to transition between the three-line peptide and the single-line peptide. The excitation peptide and the base peptide of crystalline silicon are single-line peptides, and the carriers are easily returned after being excited out, which causes the crystalline silicon to be very sensitive to impurities, which is why the purity of the silicon material used in the crystalline silicon battery is up to six. The above reasons.

“While perovskite is not sensitive to impurities, it is enough to achieve only 90% purity. Even in order to increase the strength between materials, it is also possible to actively add additives such as binders and reinforcing agents during coating. '." He believes that this is tantamount to opening up a huge space.

Perovskites are also more space-efficient in terms of conversion efficiency.

“The current laboratory efficiency of polycrystalline batteries is 22.3%, and PERC batteries have achieved 20.3%, with only two points. The laboratory efficiency of perovskite batteries is 23.7% created by the Chinese Academy of Sciences, our components. Efficiency should currently be the highest in the world, at 15.3%, and there is a gap of 8 points. There is a lot of room for improvement."

The rate of increase in the conversion efficiency of perovskite batteries is even more horrifying. Since the release of the first perovskite battery efficiency by the research team in 2012, it has grown to more than 20% in just six or seven years. It took several decades for crystalline silicon technology to achieve this efficiency.

"Even the current laboratory efficiency has exceeded polysilicon, cadmium telluride and copper indium gallium selenium, which is only second to single crystal. If this trend continues, it will definitely exceed single crystal in two or three years."

In terms of more important costs, according to the doctor's calculation, if the mass-produced perovskite module achieves 18% efficiency, its manufacturing cost will be only half or even lower than that of single crystal, and because of its lack of light, etc., its single The actual power generation of the tile is likely to be about 20% more, and the competitive advantage is very obvious.

The biggest obstacle to commercialization

Many people believe that stability is the biggest problem that commercialization of perovskite technology will face.

“If you have been paying attention to the development of perovskite technology, you will know that stability has not been a problem since 2019.”

According to him, in the past two years, the academic community has proposed a number of new formulations of perovskite materials. Under laboratory conditions, most of the formulations can achieve 1000 hours of continuous operation with less than 1% attenuation, and even less can achieve continuous work. The attenuation in 1000 hours is less than 5%.

"This has reached the technical indicators of crystalline silicon cells." He says.

In terms of other aspects of stability, he believes that it is actually a common problem between crystalline silicon components and perovskite components. "For example, packaging, technology is universal, as long as crystalline silicon can be done well, perovskite can do well, perovskite is not more afraid of water than crystalline silicon."

In terms of thermal stability, according to the internationally accepted "Double 85" test standard, their perovskite components have been tested for 1000 consecutive hours, and the attenuation is significantly less than 5%, in line with current international standards.

In the opinion of this doctor, the most important indicator is the light stability of the battery, because it directly affects the long-term benefits of photovoltaic power generation projects.

“The light decay of the early perovskite battery formulation was really serious. If the battery is not packaged, it will be finished in a month or two. This problem was solved in the material. From 2016, we can work continuously for 1000 hours. The attenuation is within 1%, and the next step is to verify the results on the component." He said that they are verifying the results through an authoritative third-party agency.

Of course, the industrialization of perovskite batteries is, after all, a work that has been developed from scratch. It is impossible to have no problems at all. He does not say this.

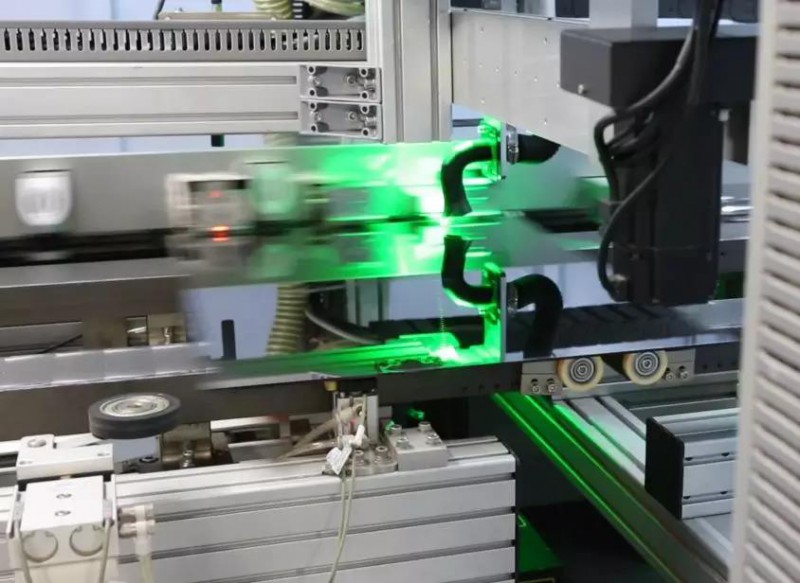

"The main technical difficulty of commercial production of perovskite is actually in the crystallization stage, which is similar to the long crystal process of pulling a single crystal, but it does not need to pull the temperature of the single crystal. This is a need to control the crystal as needed. The state of growth process requires not only that the crystals grow densely and neatly, but also that the dimensions are uniform and appropriate, and that there are no pores between them."

It is not difficult to do this in a few square meters of the laboratory, but it is not so easy to apply it evenly on an area of one or two square meters during mass production. He said that this step is the most difficult to overcome, and there is no ready-made equipment and technology in the market, it is entirely up to me to develop and explore.

“This is a difficult point for the entire technology and the biggest challenge for commercial mass production.”

However, "the current component efficiency has been more than 15%. It has opened up the development space of the entire technology, and the stability has been verified. With these two points, the general trend of technology development is already clear, even if we can't do it, There must be others who can do it.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite