The application scenarios of new energy cables mainly include three types of interior lines, charging guns/charging piles and on-board charging. The high-voltage wiring harness in the vehicle mainly provides high-voltage and high-power power supply for new energy vehicles, and is high in new energy vehicles. Safety components, with large voltage / high current, large number of large wire diameters, etc., which also makes the design of high-voltage harnesses in new energy vehicles face many challenges. Today, let's take a look at the wiring harness design and wiring requirements for new energy vehicles.

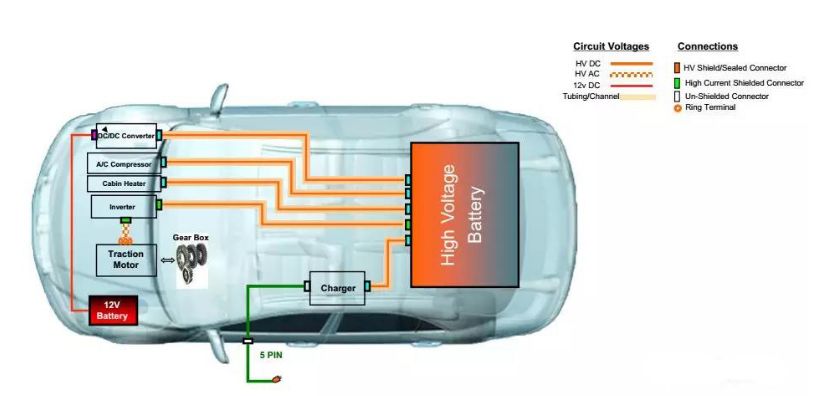

Typical pure electric vehicle high voltage harness example

First, the basic characteristics of the high-voltage harness in the car

1. Large voltage / high current

The new energy vehicle battery voltage can reach 600V, corresponding to the wire withstand voltage rating of 300A. The battery voltage of the traditional fuel car is generally 12V, and the corresponding wire withstand voltage level is less than 60V.

2. Large number of large diameter wires

New energy vehicles need to use large-diameter wires in high-voltage batteries, inverters, transformers, low-voltage batteries, air-conditioning compressors, etc., and the number is very large.

Second, the challenges facing the high-voltage wiring harness in the car

Due to the characteristics of large voltage/high current and large number of large-diameter wires, the design of the wiring harness faces challenges such as safety, wiring, shielding, weight and cost. In the face of these challenges, we have summarized some countermeasures.

Safety

In the face of security challenges, some measures need to be taken in the selection and sealing of wires in the car.

(1) Wire selection

Use high voltage wire 600V/900V (AC) (refer to ISO19642);

Adopting a high wall thickness, the wall thickness is 0.6mm-1.1mm;

Heat resistant wire, heat resistant to 150 degrees or more

Silicone rubber wire, cross-linked polyethylene / cross-linked polyolefin material

Wire outer protection

(2) Seal

It is matched with high-voltage connectors and sealed with wire seals, heat-shrink tubing, Pass-thru seals, rubber parts, etc. for waterproof and dustproof (IP67, IP69K). The wire is required to have good roundness, dimensional stability, and aging properties.

Connection seal

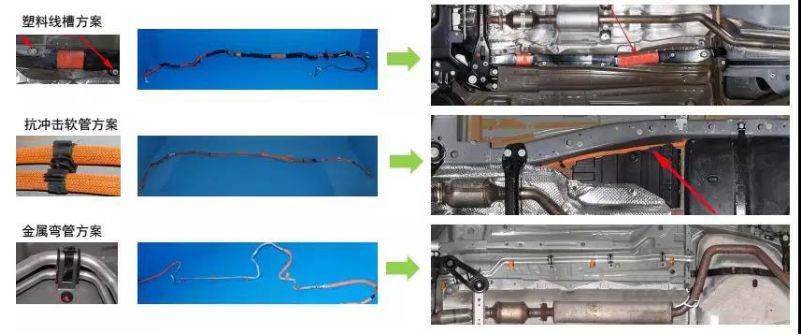

2. Wiring

The high voltage wiring harness in the car has the following requirements:

(1) Under the condition of static load, the minimum turning radius is 4 times the outer diameter of the wire;

(2) Under the condition of dynamic load, the minimum turning radius is 8 times the outer diameter of the wire;

(3) The minimum distance between the high and low voltage wires is not less than 100mm;

(4) The distance from the outlet end of the high-voltage connector to the first fixed point is not more than 100mm, and the distance between adjacent fixed points is generally not more than 150~200mm;

(5) The high-voltage harness is placed as far as possible on the bottom of the vehicle;

(6) Wire selection of ductile wires such as silicone rubber wires, flexible crosslinked polyolefin wires.

3. Shielding

Because of the electromagnetic field interference caused by high-voltage and large AC of new energy vehicles, and the electromagnetic interference generated by the rapid switching of electrical components, the entire high-voltage system is completely covered by the shielding layer in consideration of electromagnetic interference. Then the measures of high voltage harness shielding electromagnetic interference are:

(1) Select shielded wire

The ultra-high current and voltage of electric vehicles will cause a large electromagnetic induction phenomenon during operation. If the electromagnetic shielding problem is not solved well, it will inevitably affect the performance of automotive electronic equipment. Therefore, the choice of shielded wires as the high-voltage line of electric vehicles is for electromagnetic shielding. A good choice.

The shielded wire is woven by a plurality of tin-plated annealed copper wires. The thin copper wire can maintain the design flexibility, and has a coverage of more than 90%. It is necessary to control the reasonable insulation and sheath peeling force to meet the requirements of the wire stripping processing.

(2)Bundle Shielding

For overall shielding, the wires are unshielded and are currently used by Japanese OEMs.

Bundle Shielding refers to the protection of the wire harness against electromagnetic interference when the wire bundle is fixed as a shield member with a light braided metal shield

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite